People

As a business of Worthington Enterprises, Ragasco follows the company’s people-first, Golden Rule-based Philosophy. We continue our journey of a safe and inclusive working environment where our diverse workforce is treated with dignity and respect in a culture of well-being. It’s our commitment to provide tools, training and resources to support our employees in their professional and personal goals. All employees of Worthington Enterprises are empowered to innovate, thrive and grow.

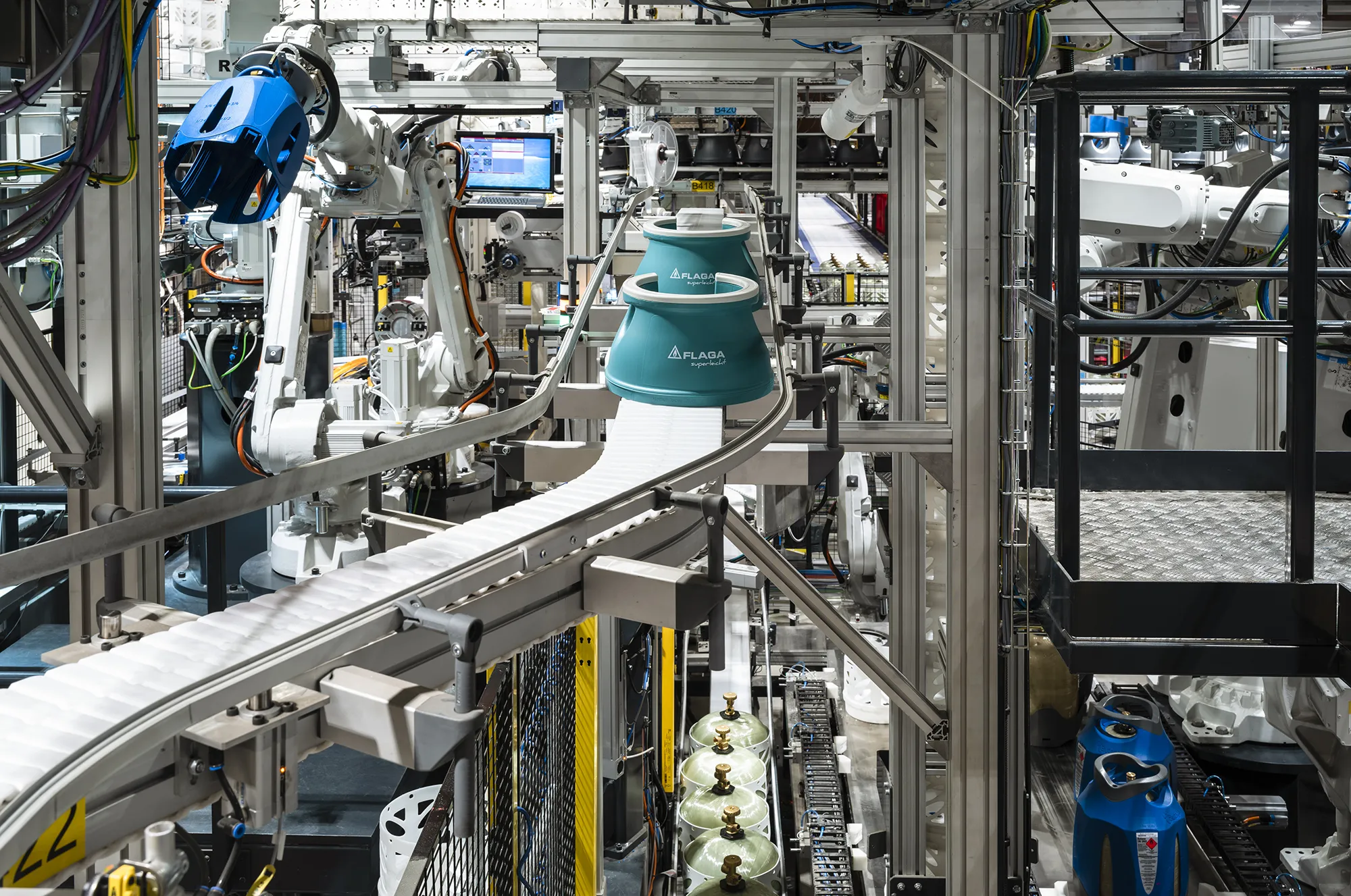

Ragasco composite cylinders are a light, easy-to-handle and safe power source for users in need of clean, affordable and readily available energy.